AT70PSI

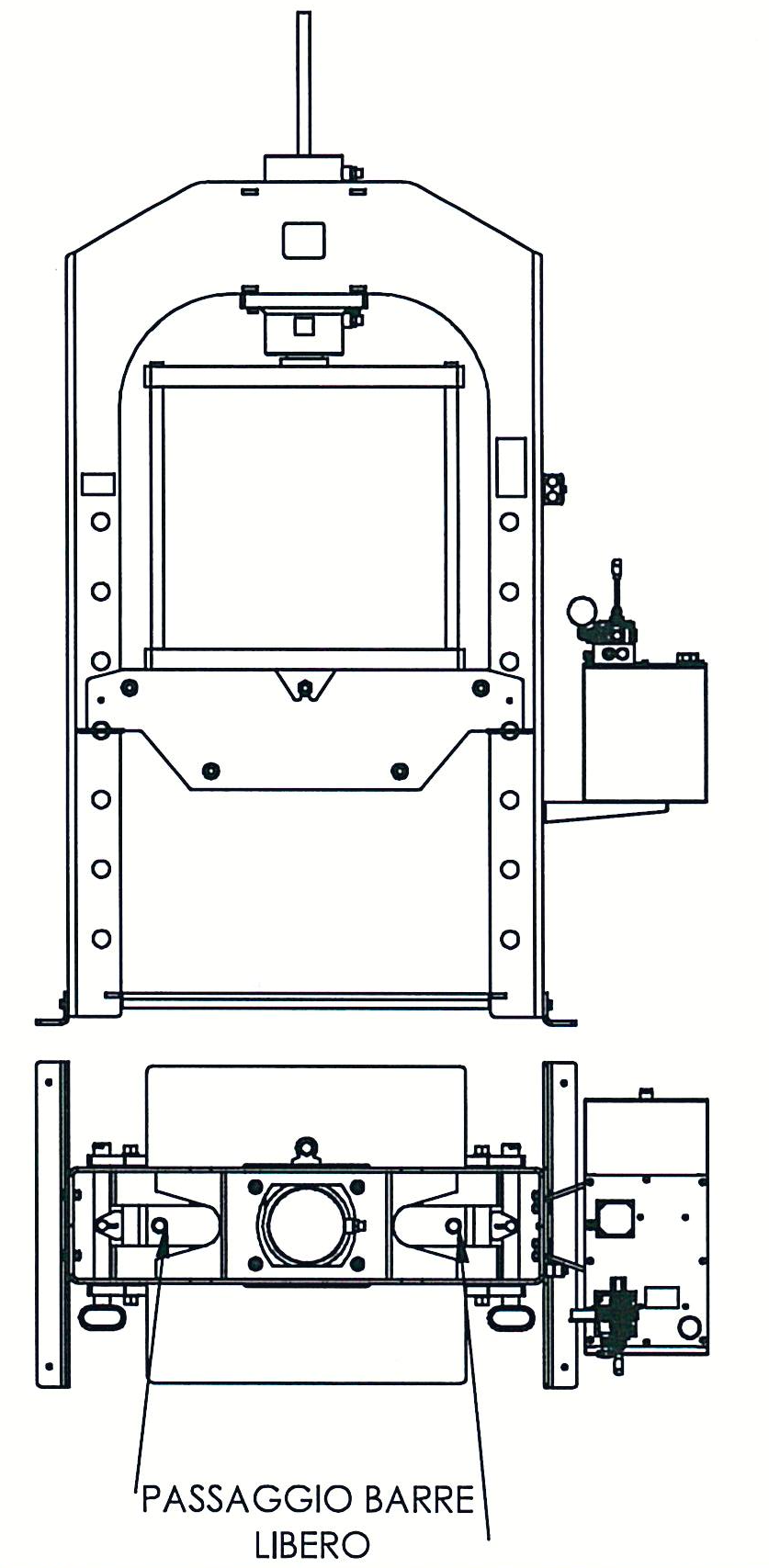

Motorized Hydraulic Press Power 70 TON with Double Milled Plate and Anti-rotation.

Max Capacity (Ton)

Weight (Kg)

Max Pressure (Bar)

Cylinder Stroke (mm)

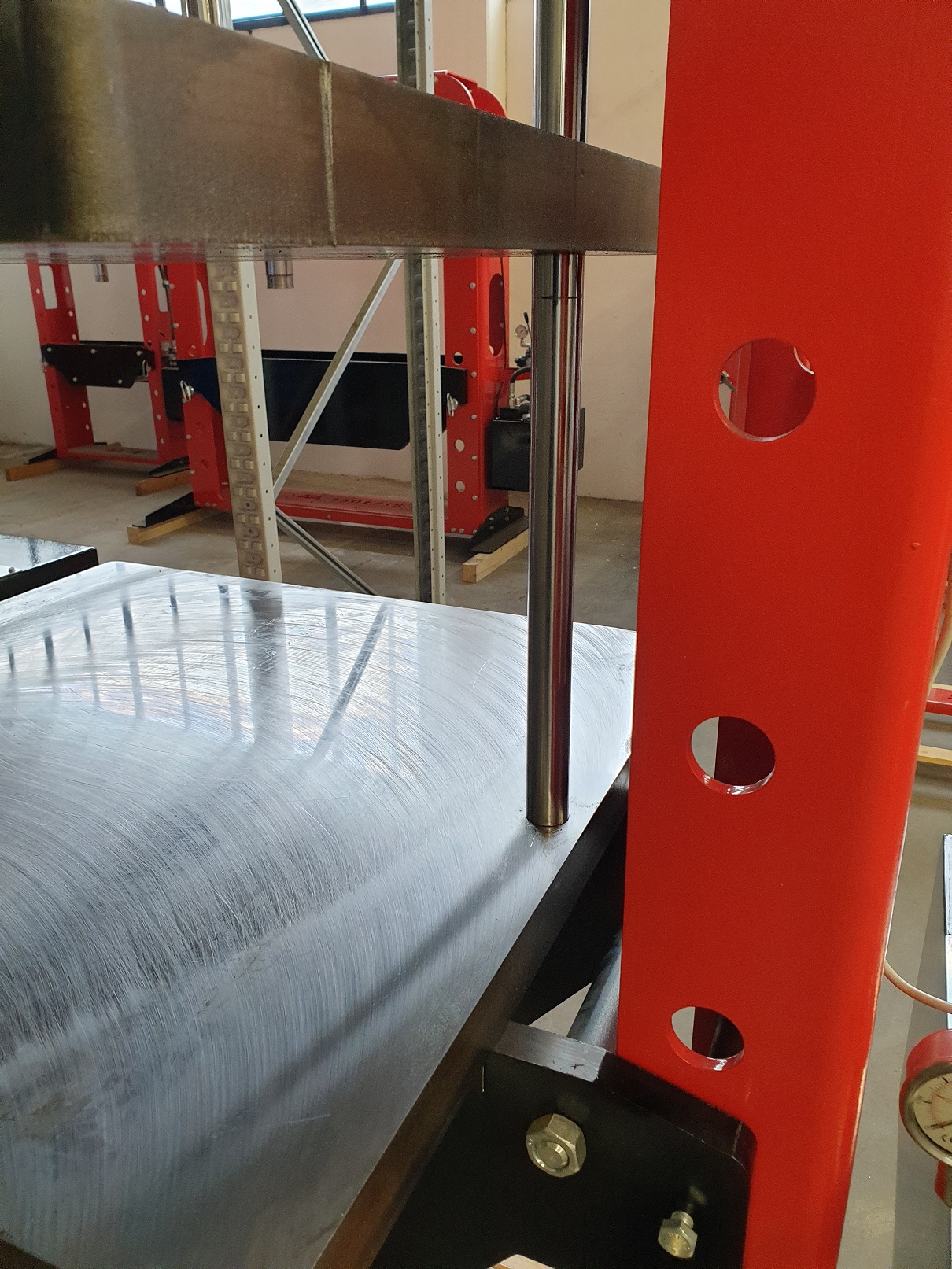

Motorized Hydraulic Press Power 70 TON with Double Milled Plate

- Cylinder anti-rotation

- Plate fixed on lower pallet

- Plate fixed on cylinder rod

- 2 side guide pins

The lifting and lowering of the pallet can be done by affixing chains and/or lifting bands fixed on the upper pallet and positioned in a balanced manner on the lower pallet to prevent the pallet from lifting/lowering in an uneven and/or non-uniform way. Once these chains and/or bands have been affixed, it is possible to operate the 2-hand controls (button + distributor lever) to exploit the driving force of the hydraulic power unit. Before lifting or lowering the pallet, after securing it to the chains and/or bands, remove the fixing pins on the holes of the presses with locking pins. Move the pallet to the desired position. Reposition pins and pins. Remove chains and bands.

MAIN FEATURES

| Weight (Kg) | 550 |

|---|---|

| Max pressure (bar) | 350 |

| Max Capacity (tons) | 70 |

| Max capacity in fast mode (l/min) | 33 |

| Max capacity in slow mode (l/min) | 5 |

| Tension (V) | 400 |

| Frequency (Hz) | 50-60 |

| Motor Power (kW) | 3 |

| Max power absorbed (A) | 5,5 |

| Cylinder stroke (mm) | 300 |

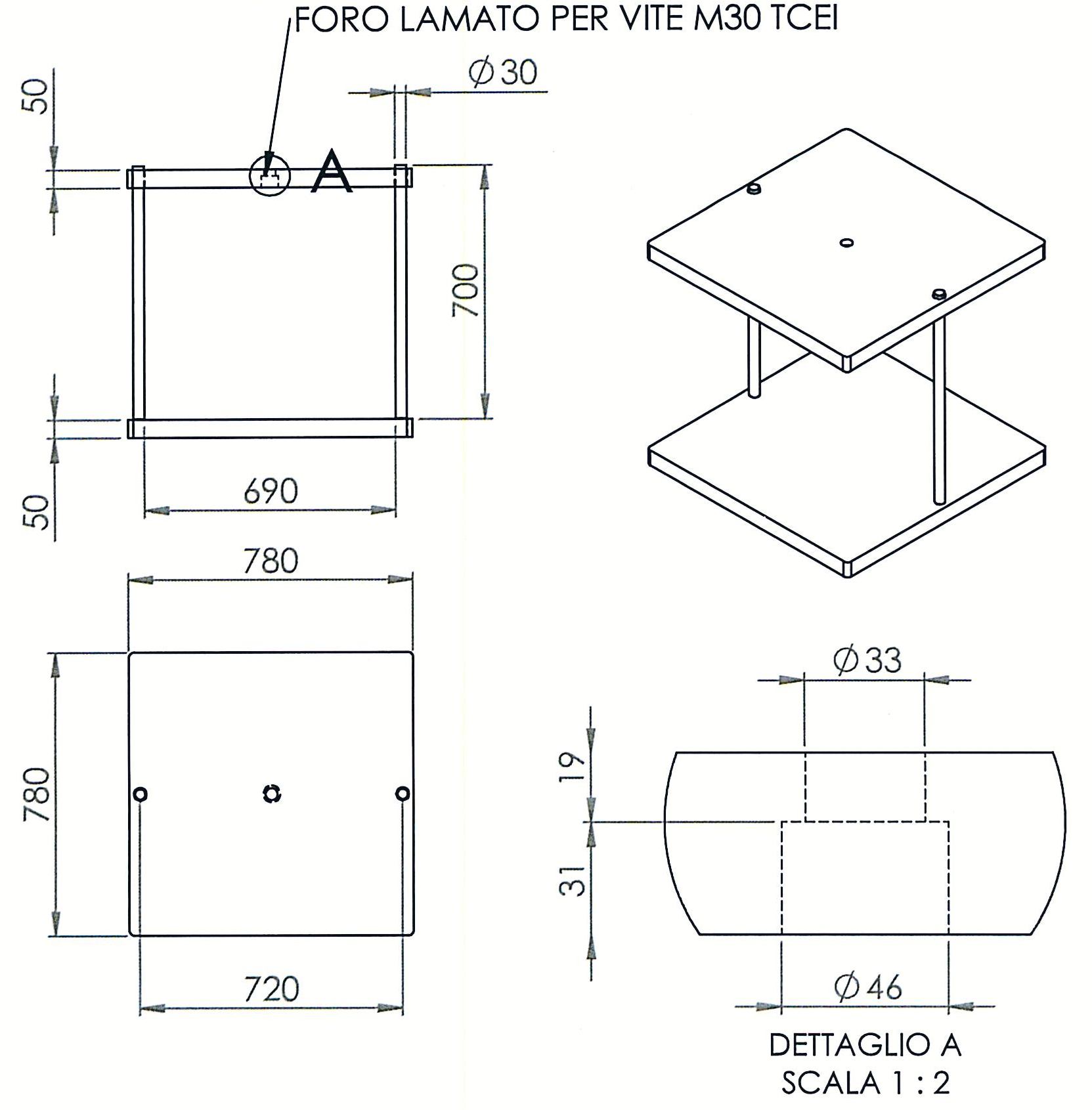

| Shank diameter (mm) | M30 |

| Tank capacity (liters) | 50 |

AxA Group produces a complete range of OPTIONALS and ACCESSORIES:

- plates, V-prisms, milled and T-slot worktops

- front and rear perimeter guards

- up and down limit switch microswitch

- RAPID/SLOW control system for operating the press with one hand within the limits set by current legislation

- switchboards for automatic presses with PLC

- increased cylinder rod strokes

All our presses are always accompanied by a user and maintenance manual, CE marking and a certificate of conformity in accordance with the current machinery directive and workplace safety directives.

Our hydraulic presses are manufactured with the highest construction quality and guarantee unlimited reliability.

Motorized Hydraulic Press Power 70 TON with Double Milled Plate

- Cylinder anti-rotation

- Plate fixed on lower pallet

- Plate fixed on cylinder rod

- 2 side guide pins

The lifting and lowering of the pallet can be done by affixing chains and/or lifting bands fixed on the upper pallet and positioned in a balanced manner on the lower pallet to prevent the pallet from lifting/lowering in an uneven and/or non-uniform way. Once these chains and/or bands have been affixed, it is possible to operate the 2-hand controls (button + distributor lever) to exploit the driving force of the hydraulic power unit. Before lifting or lowering the pallet, after securing it to the chains and/or bands, remove the fixing pins on the holes of the presses with locking pins. Move the pallet to the desired position. Reposition pins and pins. Remove chains and bands.