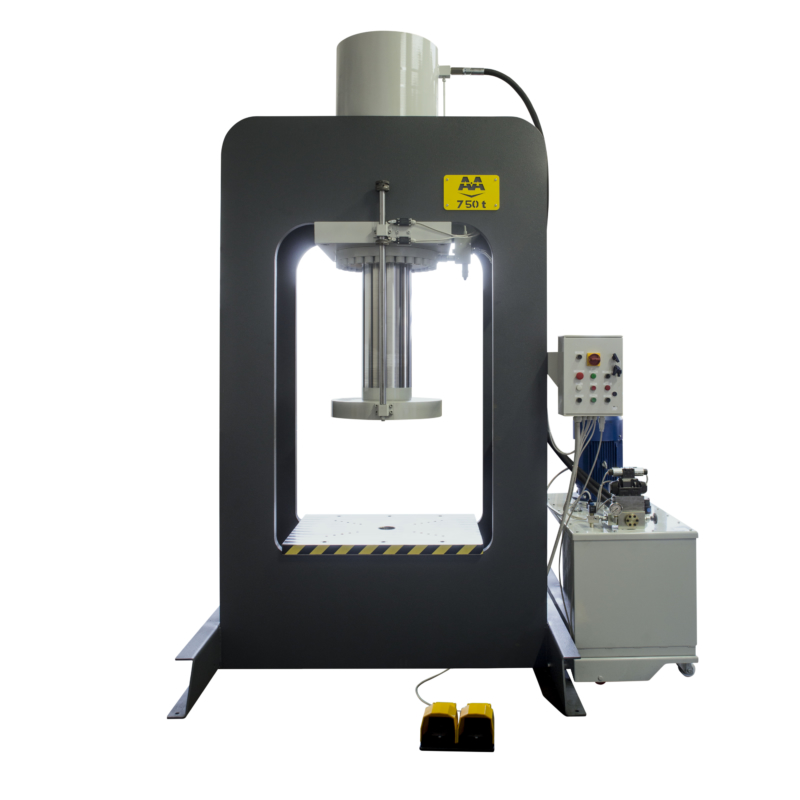

AXATOP750

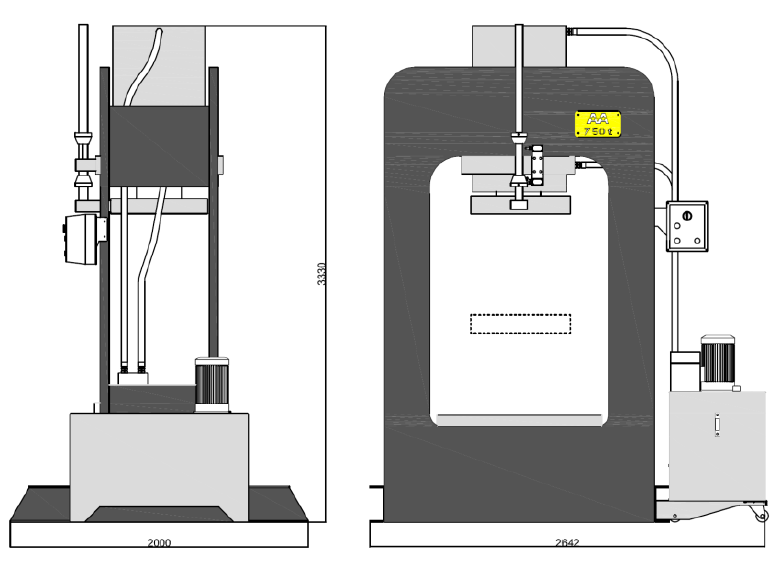

750 ton hydraulic press with 250 liter hydraulic power unit.

Max Capacity (Ton)

750

Weight (Kg)

8500

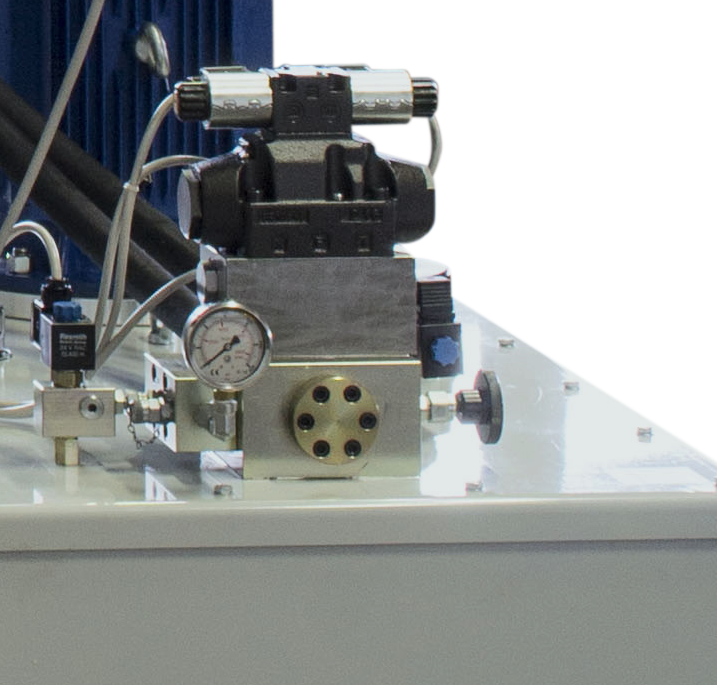

Max Pressure (Bar)

380

Cylinder Stroke (mm)

800

750 tons hydraulic press with 250 liter hydraulic power unit.

- Fast speed is achieved with two-handed control

- Weight 8500 kg

- Work plate with central hole 100mm

- Cylinder operated (up/down) by remote control with pedal

- Mobile adjustment of the limit switches (adjustable by the operator)

- Paint color RAL7011

MAIN FEATURES

| Max pressure (bar) | 380 |

|---|---|

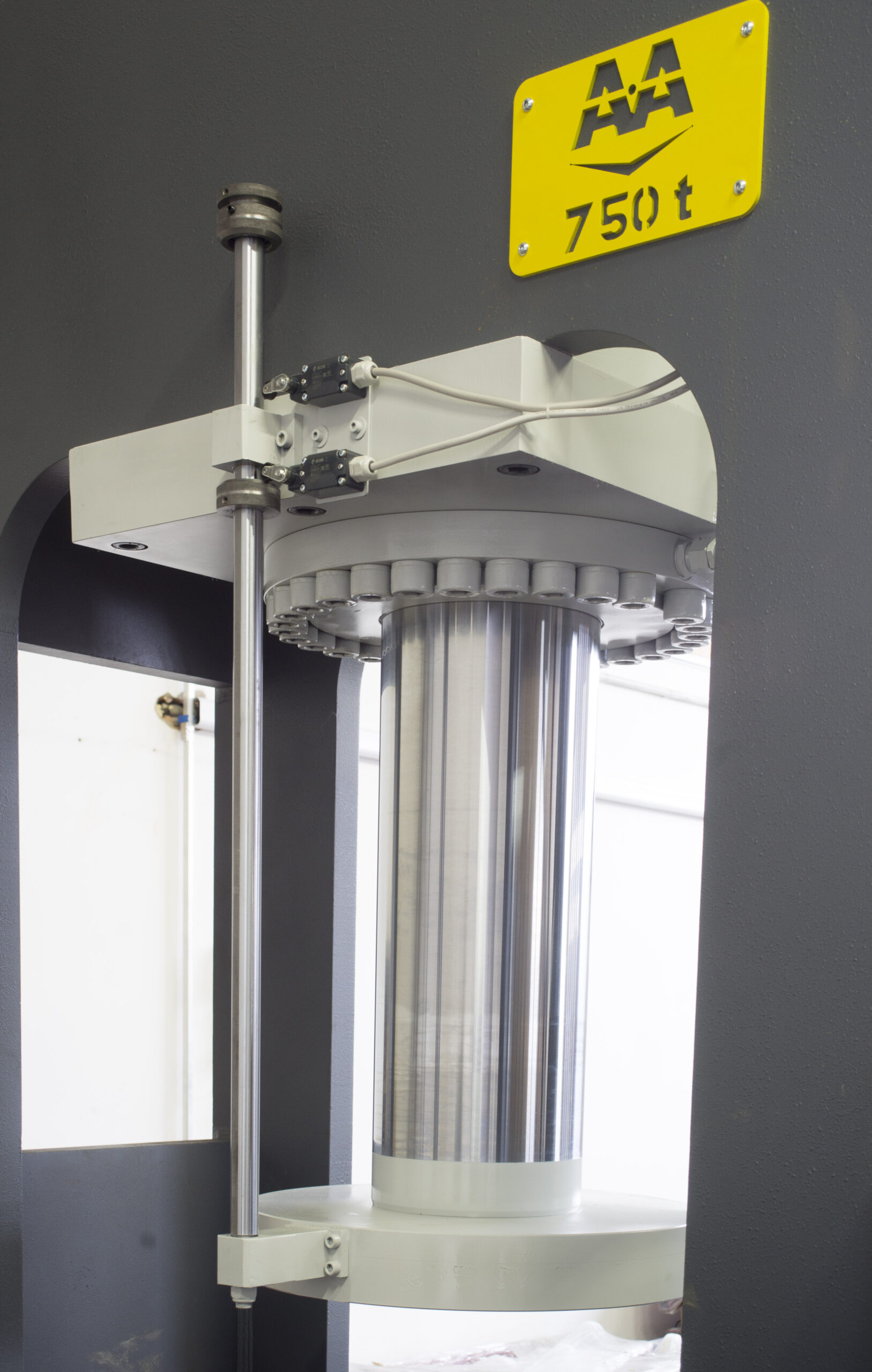

| Cylinder stroke (mm) | 800 |

| Stem diameter (mm) | 300 |

AxA Group produces a complete range of OPTIONALS and ACCESSORIES:

- plates, V-prisms, milled and T-slot worktops

- front and rear perimeter guards

- up and down limit switch microswitch

- RAPID/SLOW control system for operating the press with one hand within the limits set by current legislation

- switchboards for automatic presses with PLC

- increased cylinder rod strokes

All our presses are always accompanied by a user and maintenance manual, CE marking and a certificate of conformity in accordance with the current machinery directive and workplace safety directives.

Our hydraulic presses are manufactured with the highest construction quality and guarantee unlimited reliability.

750 tons hydraulic press with 250 liter hydraulic power unit.

- Fast speed is achieved with two-handed control

- Weight 8500 kg

- Work plate with central hole 100mm

- Cylinder operated (up/down) by remote control with pedal

- Mobile adjustment of the limit switches (adjustable by the operator)

- Paint color RAL7011